Reliable, Proven Technology

Proven Technology for Demanding Applications

High Efficiency and Reliability

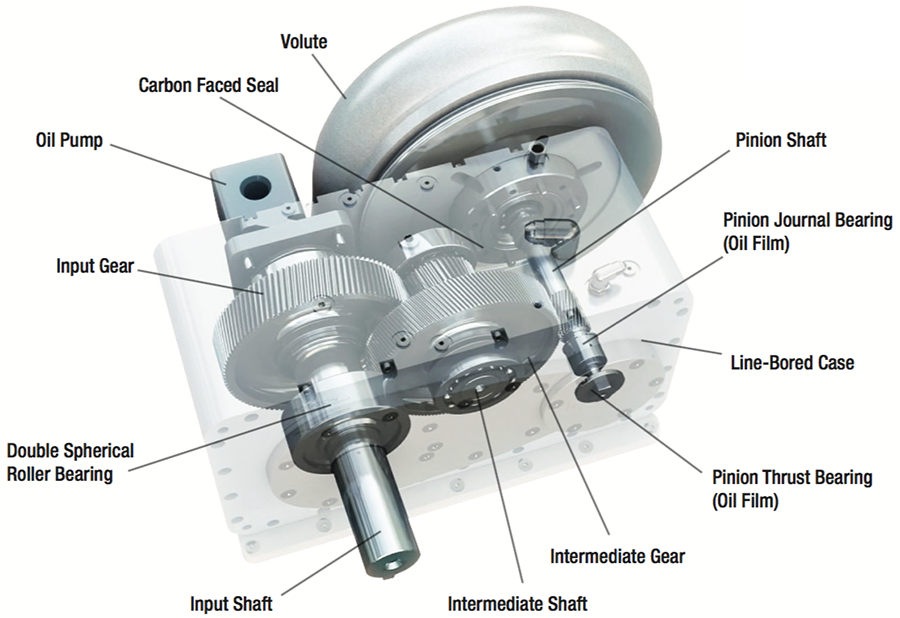

Inovair’s 2200 blower is an integrally-geared single stage high efficiency centrifugal blower. This geared centrifugal design is the preferred standard for applications where efficiency and reliability are paramount, such as gas turbines (aircraft and stationary), pipeline and oil fed compressors, air-conditioning and refrigeration. The Inovair 2200 utilizes non-contact oil film bearings with an integrally geared design. The highly durable gearbox is integrated into the blower unit providing the necessary impeller speed with traditional 1800 or 3600 rpm electric motors, with no need for exotic high-speed electric motors or high frequency VFD’s.

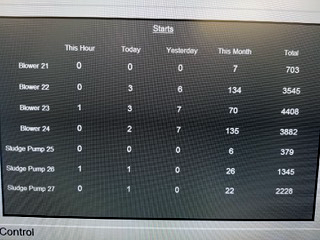

Inovair blowers and blower packages are built without the electrical component complexity seen in air bearing and mag bearing high-speed turbo blowers. Instead, a simpler design using industry standard components allows for greater reliability and easy maintenance at the plant level. Inovair’s durable geared centrifugal design allows reliable operation in dusty environments, as well as applications with frequent start/stop cycles, which can cause air bearing turbo blowers to fail.

Inovair blowers and blower packages are built without the electrical component complexity seen in air bearing and mag bearing high-speed turbo blowers. Instead, a simpler design using industry standard components allows for greater reliability and easy maintenance at the plant level. Inovair’s durable geared centrifugal design allows reliable operation in dusty environments, as well as applications with frequent start/stop cycles, which can cause air bearing turbo blowers to fail.

| • Proven integrally geared design |

| • Non-Contact oil-film bearings not affected by starts/stops |

| • Operates reliably in varying pressure applications |

| • Tolerant of industry and dirty environments |

| • Can be installed outdoors without a cover |

Relative to positive displacement blowers, centrifugal technology is inherently more efficient and longer lasting than positive displacement designs. For applications where efficiency and durability are most important, such as aerospace, municipal wastewater, petroleum exploration, and natural gas compression, centrifugal/turbo compressors are the industry standard.