Rise to Surge

What is rise to surge?

Surge is a phenomenon in a centrifugal blower or compressor where the maximum head and minimum flow is reached.

Surge is a phenomenon in a centrifugal blower or compressor where the maximum head and minimum flow is reached. To understand stand how and why surge occurs, we first have to understand the working principal of a centrifugal blower. The blower’s impeller is used to increase the kinetic energy of the air. In the volute the kinetic energy is slowed and converted to potential energy in the form of a pressure rise. As long as the outlet pressure of the blower is greater than the downstream pressure, the blower operates smoothly and efficiently. If the blower is slowed down enough or the downstream pressure rises suddenly beyond the capacity of the blower surge will occur. Because the pressure downstream is now greater than the capacity of the blower, the air will now reverse and try to flow back into the blower. As the air reverse flows back into the volute the pressure will decrease again and the blower’s pressure will overcome this loss until it slows again. This cycle, known as surge, will go on until the reason for this surge is corrected. This phenomenon can be detrimental to some centrifugal compressors so it is important to accurately know the surge point of your blower being specified and how it’s control system, if equipped, avoids surge conditions.

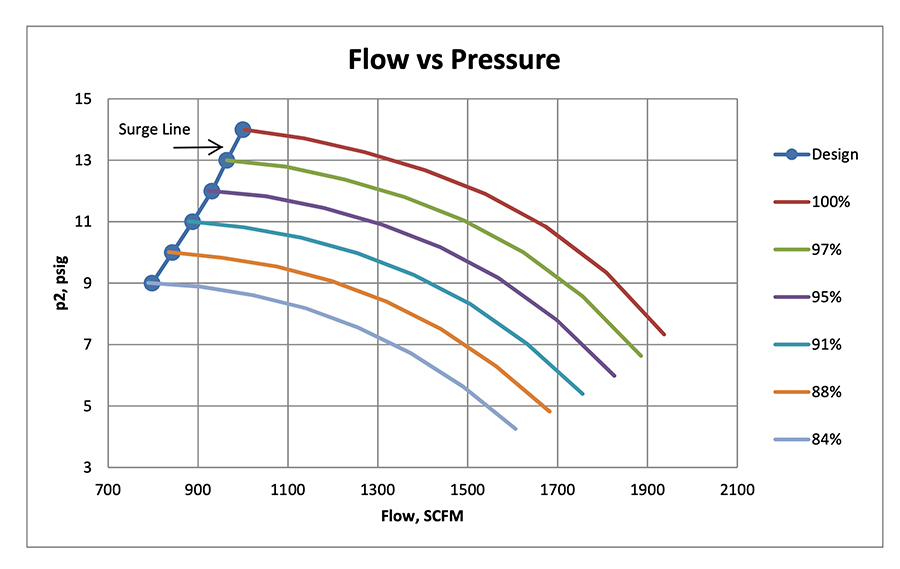

Centrifugal blower manufacturers should provide curves which show a collection of surge points for varying speeds and pressures. This line is called the surge line. This is the point where the blower will start to experience surge and should not be a point in your design.

Methods to Control Surge

• Downstream Modulating Valve

• Blow off valve

• Speed Control

• Turn off Blower

• Surge Boundary 0.3 psi rise to surge along constant speed line

One of the first methods used to try and protect the blower is to add a modulating valve downstream of the blower. If the pressure in discharge line is too high the modulating valve will open reducing the header pressure thus relieving the surge condition. However there is a concern this valve could reduce the header pressure too much and eliminate air flow to the process. This usually occurs after surge has started and does not eliminate surge.

Another method used to protect against surge is a blow of valve (BOV) on the blower. If the blowers monitor detects surge the blowers BOV opens discharging the process air to atmosphere until either the blower’s speed is turned up, the blower shuts down, or this reason for the surge is corrected. If the surge boundary is not adequate this method alone cannot protect against surge.

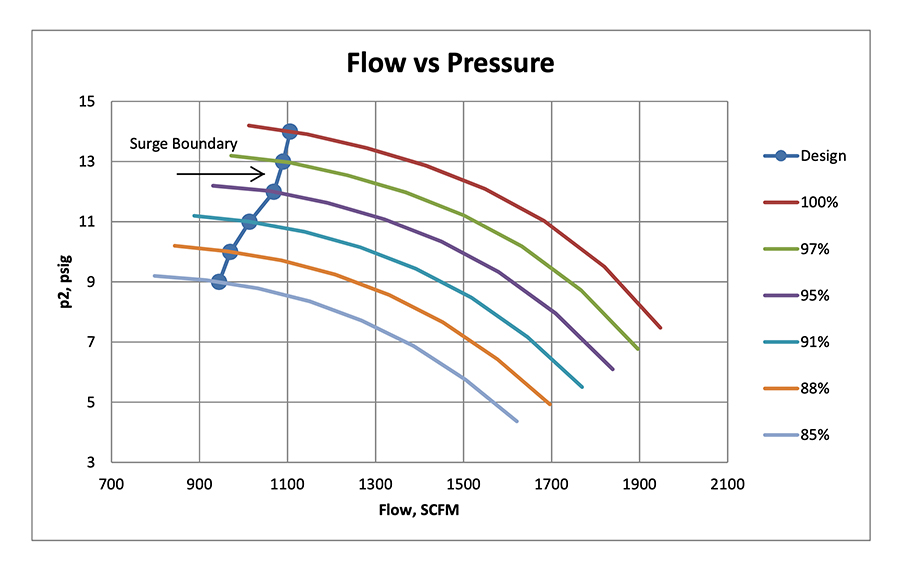

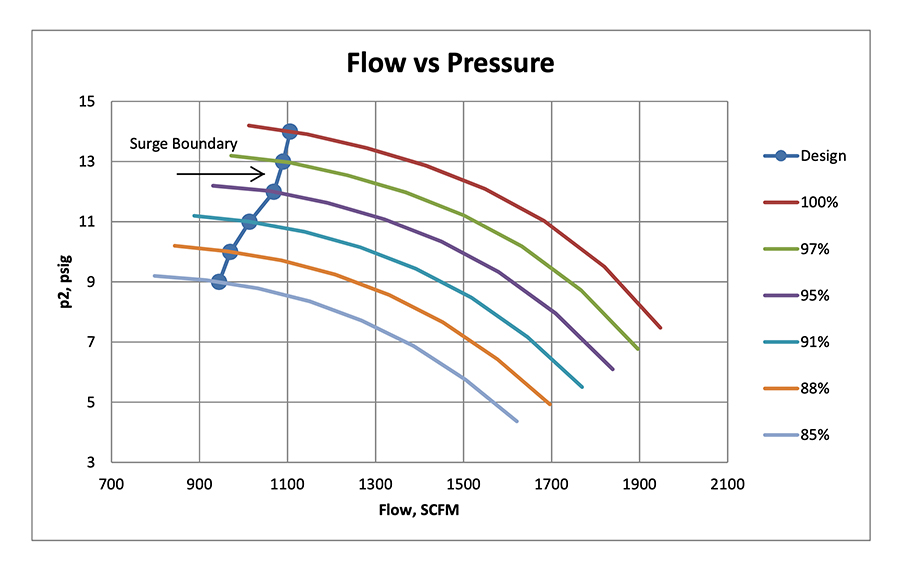

The ideal way to protect against surge is to have a surge boundary defined on the blower’s performance curve in conjunction with a BOV. Since most instruments alone are slow to detect surge a buffer called the surge boundary provides the BOV enough time to react. This surge boundary should be set so that the minimum flow the blower can run at a specific pressure and speed is equal to the surge point for a pressure 0.3 psi higher along that same speed curve. This ensures enough reaction time for the BOV to open if for some reason the header pressure rises beyond the blower’s capability. The limitation for this method is some blower manufactures curves are relatively flat and if a surge boundary of 0.3 psi rise to surge along constant speed line is set they would not provide 50% turndown. It is important for the specifier to confirm a minimum 50% turndown and the surge boundary limit.

Surge is a natural phenomenon and with proper protection and understanding an engineer should be able to limit any operational concerns in their design.

• Blow off valve

• Speed Control

• Turn off Blower

• Surge Boundary 0.3 psi rise to surge along constant speed line

One of the first methods used to try and protect the blower is to add a modulating valve downstream of the blower. If the pressure in discharge line is too high the modulating valve will open reducing the header pressure thus relieving the surge condition. However there is a concern this valve could reduce the header pressure too much and eliminate air flow to the process. This usually occurs after surge has started and does not eliminate surge.

Another method used to protect against surge is a blow of valve (BOV) on the blower. If the blowers monitor detects surge the blowers BOV opens discharging the process air to atmosphere until either the blower’s speed is turned up, the blower shuts down, or this reason for the surge is corrected. If the surge boundary is not adequate this method alone cannot protect against surge.

The ideal way to protect against surge is to have a surge boundary defined on the blower’s performance curve in conjunction with a BOV. Since most instruments alone are slow to detect surge a buffer called the surge boundary provides the BOV enough time to react. This surge boundary should be set so that the minimum flow the blower can run at a specific pressure and speed is equal to the surge point for a pressure 0.3 psi higher along that same speed curve. This ensures enough reaction time for the BOV to open if for some reason the header pressure rises beyond the blower’s capability. The limitation for this method is some blower manufactures curves are relatively flat and if a surge boundary of 0.3 psi rise to surge along constant speed line is set they would not provide 50% turndown. It is important for the specifier to confirm a minimum 50% turndown and the surge boundary limit.

Surge is a natural phenomenon and with proper protection and understanding an engineer should be able to limit any operational concerns in their design.