PTC 13 promotes consistency in performance evaluations but also facilitates fair comparisons between different blower models.

Why ASME PTC 13 Testing Is Important

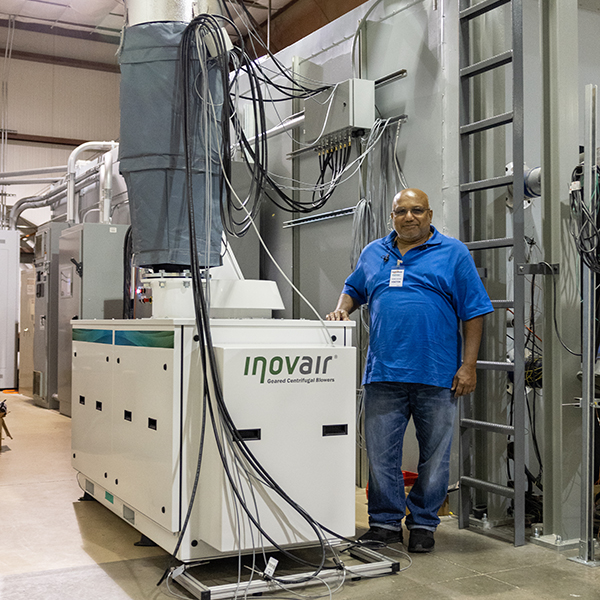

Inovair recently implemented testing facilities and processes outlined in PTC 13, recognizing the significance it holds for the accurate selection of blowers for various applications. By adhering to these guidelines, we ensure a standardized and reliable method for evaluating the performance of our blowers in various applications. By aligning our testing procedures with PTC 13, we demonstrate our commitment to delivering accurate and trustworthy performance data to customers, enabling them to make informed decisions regarding blower selection and optimization for their specific plant requirements. As part of that committment, one of Inovair's engineers is on the ASME PTC 13 committee.

What is PTC 13?

ASME PTC 13 is a newly developed test code that enables precise performance comparisons between positive displacement and dynamic (centrifugal) blowers. This code outlines procedures for accurately determining the total operating electrical power required for a packaged blower system, also known as the "wire-to-air" performance. In this article, we will review the key aspects of ASME PTC 13 and explore the significance of this important standard.

Why Were the Old Test Codes Inadequate?

ASME Test Codes PTC 9 and PTC 10, which were developed for positive displacement and dynamic machines respectively, have become inadequate for current technologies and the evolving demands of customers and the market.

PTC 9, now inactive, is available only for historical reference purposes.

The shortcomings of PTC 10 include:

1. Measuring the flow at the blower inlet assumes that all the air entering the blower comes out of the discharge connection, which may not be accurate.

2. PTC 10 does not refer to the "wire-to-air" performance of packaged blower systems that include high-speed motors, variable frequency drives, controls, and filtration.

3. PTC 10 does not address the testing of blower systems. It focuses on testing only the blower core and ignores the potential heat transfer and pressure differentials inside enclosures or boxes.

4. PTC 10 does not provide guidelines for contractual guarantees, and commercial items are outside the scope of this test code.

The shortcomings of PTC 9 and PTC 10 led to the development of a new test code, ASME PTC 13, which provides more accurate performance comparisons for both positive displacement and dynamic (centrifugal) blowers.

PTC 9, now inactive, is available only for historical reference purposes.

The shortcomings of PTC 10 include:

1. Measuring the flow at the blower inlet assumes that all the air entering the blower comes out of the discharge connection, which may not be accurate.

2. PTC 10 does not refer to the "wire-to-air" performance of packaged blower systems that include high-speed motors, variable frequency drives, controls, and filtration.

3. PTC 10 does not address the testing of blower systems. It focuses on testing only the blower core and ignores the potential heat transfer and pressure differentials inside enclosures or boxes.

4. PTC 10 does not provide guidelines for contractual guarantees, and commercial items are outside the scope of this test code.

The shortcomings of PTC 9 and PTC 10 led to the development of a new test code, ASME PTC 13, which provides more accurate performance comparisons for both positive displacement and dynamic (centrifugal) blowers.

Benefits of PTC 13

PTC 13 provides a comprehensive checklist of components and boundaries that need to be considered within the blower system, ensuring that no critical aspects are overlooked during the testing process. This not only promotes consistency in performance evaluations but also facilitates fair comparisons between different blower models. Additionally, PTC 13 addresses important considerations such as allowable power tolerance, penalty for performance shortfalls, and the evaluation of multiple blowers for the same application.

Certification Process for PTC 13

To get certified to run ASME PTC 13-2018 in-house, a company must meet certain requirements and undergo a certification process. Here are some of the key steps and requirements:

1. Train personnel: The company must ensure that personnel involved in testing and evaluating PTC thermistors are properly trained and qualified to perform the testing according to the standard. This may involve attending training courses or workshops offered by ASME or other authorized providers.

2. Establish a quality assurance program: The company must establish a quality assurance program that meets the requirements of ASME PTC 13-2018. This program should ensure that all testing is performed consistently and accurately, and that all equipment used in the testing is properly calibrated and maintained.

3. Develop test procedures: The company must develop test procedures that are consistent with the requirements of ASME PTC 13-2018. These procedures should specify the equipment, instrumentation, and techniques used in the testing.

4. Perform proficiency testing: The company must perform proficiency testing to demonstrate that its personnel are capable of performing the testing according to the standard. Proficiency testing involves performing the testing on a known sample and comparing the results to a reference value.

1. Train personnel: The company must ensure that personnel involved in testing and evaluating PTC thermistors are properly trained and qualified to perform the testing according to the standard. This may involve attending training courses or workshops offered by ASME or other authorized providers.

2. Establish a quality assurance program: The company must establish a quality assurance program that meets the requirements of ASME PTC 13-2018. This program should ensure that all testing is performed consistently and accurately, and that all equipment used in the testing is properly calibrated and maintained.

3. Develop test procedures: The company must develop test procedures that are consistent with the requirements of ASME PTC 13-2018. These procedures should specify the equipment, instrumentation, and techniques used in the testing.

4. Perform proficiency testing: The company must perform proficiency testing to demonstrate that its personnel are capable of performing the testing according to the standard. Proficiency testing involves performing the testing on a known sample and comparing the results to a reference value.

Considerations When Employing PTC 13

It is important to note that this test code is not fully autonomous. The person responsible for specifying the requirements still needs to actively engage and put forth effort to achieve the desired outcomes. There are several decisions that need to be made, such as:

1. Define test operating points. While it requires some informed estimation, it is crucial to specify the operating points that closely reflect the conditions in which the blower will be used at your facility. Often, specifications include the highest historical ambient temperature along with 100% Relative Humidity (RH). Although this may seem like a cautious approach, further investigation reveals that this particular combination rarely, if ever, occurs. It is preferred to identify the "heat index,” a combination of ambient temperature and relative humidity.

2. Define blower system boundaries. Designed to assess the wire-to-air performance of a blower system within a controlled environment, the PTC 13 test requires the user to input the specific boundaries and components of the complete blower system.

3. Interpretation of test results. Since PTC 13 is not associated with existing commercial agreements, it is important to consider:

• The best way to compare the test results with that of other performance results, including defining the permissible power tolerance between the guaranteed and tested values.

• The penalties or remedies, if any, should the test results fall short of the guarantee. How should the performance of blowers be evaluated if they demonstrate better energy consumption on most specified points but may have a few points with higher energy consumption? Should these results be averaged, or do they stand independently?

• If multiple blowers are purchased for the same application, should all of them be tested? Do the results of each test stand independently, or should they be averaged?

1. Define test operating points. While it requires some informed estimation, it is crucial to specify the operating points that closely reflect the conditions in which the blower will be used at your facility. Often, specifications include the highest historical ambient temperature along with 100% Relative Humidity (RH). Although this may seem like a cautious approach, further investigation reveals that this particular combination rarely, if ever, occurs. It is preferred to identify the "heat index,” a combination of ambient temperature and relative humidity.

2. Define blower system boundaries. Designed to assess the wire-to-air performance of a blower system within a controlled environment, the PTC 13 test requires the user to input the specific boundaries and components of the complete blower system.

3. Interpretation of test results. Since PTC 13 is not associated with existing commercial agreements, it is important to consider:

• The best way to compare the test results with that of other performance results, including defining the permissible power tolerance between the guaranteed and tested values.

• The penalties or remedies, if any, should the test results fall short of the guarantee. How should the performance of blowers be evaluated if they demonstrate better energy consumption on most specified points but may have a few points with higher energy consumption? Should these results be averaged, or do they stand independently?

• If multiple blowers are purchased for the same application, should all of them be tested? Do the results of each test stand independently, or should they be averaged?

Inovair is Equipped With PTC 13 Test Facilities

Inovair’s implementation of testing facilities and processes outlined in PTC 13 underscores the company's dedication to excellence and meeting the needs of our customers. By adhering to these standardized guidelines, Inovair ensures that its blowers are rigorously evaluated for performance across a range of applications. This commitment to accuracy and reliability empowers customers to make informed decisions when it comes to selecting and optimizing blowers for their specific plant requirements. By providing trustworthy performance data, Inovair contributes to the overall efficiency and success of industrial operations, fostering a stronger partnership between the company and its valued customers. Through the adoption of PTC 13, Inovair sets a benchmark for quality and professionalism in the blower industry, cementing its position as a trusted and innovative leader.

Let's Talk

Need a quote?

Want to learn more about our testing capabilities?

We're here to answer any questions you may have.

Want to learn more about our testing capabilities?

We're here to answer any questions you may have.