Industrial Blowers

The Most Reliable, Cost Effective and

Efficient Blowers

Inovair revolutionizes the blower industry with their geared centrifugal blowers, offering unparalleled efficiency and durability while maintaining the lowest total ownership cost in the market. The secret lies in their ingenious high-efficiency design, which not only delivers exceptional performance but also remains affordable. This achievement is made possible by utilizing industry standard components, eliminating unnecessary complexity and reducing costs. Furthermore, Inovair's extensive experience in designing and manufacturing compact blowers contribute to their ability to provide cost-effective solutions. By adopting a proven design approach, maintenance becomes hassle-free, and the blowers exhibit remarkable durability, ensuring long-lasting performance.

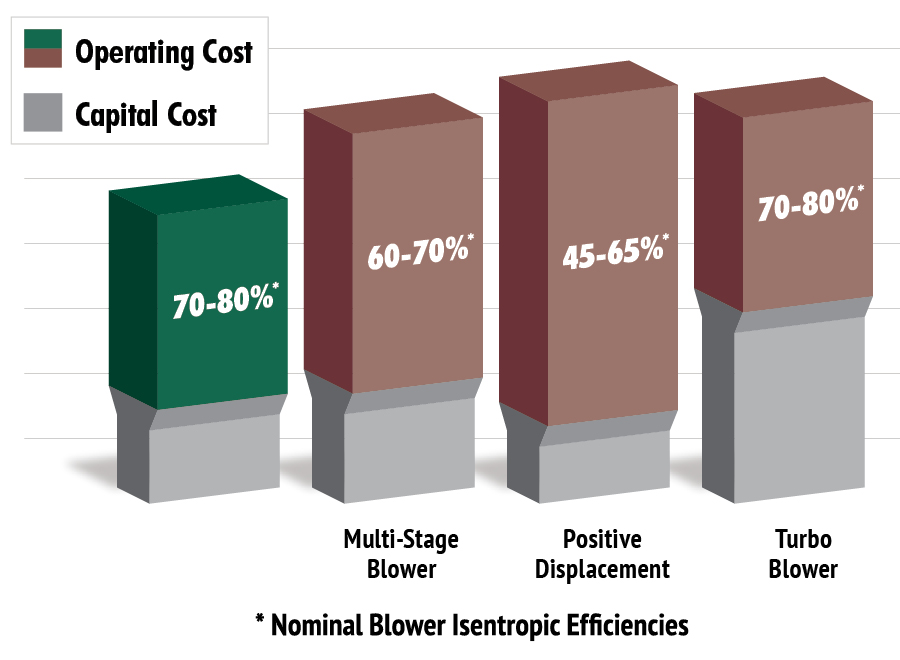

With documented energy savings as high as 45% relative to PD and multistage blowers, and without the electrical complexity and durability issues seen in high speed turbo blowers, Inovair offers a unique combination of high efficiency, reliability, and simplicity. Unlike some others, Inovair blowers and customers are supported by the advantages of a vertically integrated manufacturer, with Inovair controlling all elements of design, production, and service from the company’s headquarters in Kansas City.

With documented energy savings as high as 45% relative to PD and multistage blowers, and without the electrical complexity and durability issues seen in high speed turbo blowers, Inovair offers a unique combination of high efficiency, reliability, and simplicity. Unlike some others, Inovair blowers and customers are supported by the advantages of a vertically integrated manufacturer, with Inovair controlling all elements of design, production, and service from the company’s headquarters in Kansas City.

Proven Performance

We’ve been designing blowers for nearly 30 years, in some of the most demanding applications. From 4000+ horsepower drag race superchargers to the F-35 fighter jet deicing units, we have the experience and technology to optimize performance and durability. With thousands of Inovair units shipped, we’ve observed energy savings of up to 40%. If you are looking to reduce total cost of ownership, look no further than Inovair.

Industrial Product Line

The Inovair industrial product line consists of the IM-Series, which is completely gear driven, and the IO Series, which has both a belt drive and a gear drive. The product range covers from 25 horsepower to 500 horsepower, making our blowers a perfect fit for all industrial applications. Unlike other technologies, we employ an integrally-geared, centrifugal design that allows the blowers to operate reliably in extreme conditions.

LOWEST COST OF OWNERSHIP

When evaluating the overall expenses encompassing capital equipment purchase, installation, operation, maintenance, and the potential downtime costs caused by unforeseen equipment problems, Inovair emerges as the market leader in providing the most advantageous solution. Our primary focus in designing, manufacturing, and supporting our products is to ensure the lowest cost of ownership. Here are several key differentiators that contribute to Inovair's competitive edge:

HIGHEST EFFICIENCIES

Inovair excels at aerodynamic design. Coupled with our minimal parasitic losses, Inovair products consistently perform above 80% isentropic efficiency. This equates to a 10-45% energy savings over multi-stage or PD blowers. All impeller stages are precision machined, which allows for tight tolerances, maximum efficiency, and highest reliability.

LOW MAINTENANCE COSTS

No expensive service contracts here. Inovair products are designed to be maintained in the field by the equipment operator in just a few minutes. All our maintenance tasks have instructional videos on our website. Total cost of ownership includes the cost of servicing the unit for the useful life. Inovairs products are engineered to require the least effort and lowest cost to maintain.

MINIMAL DOWNTIME

Not only does Inovair offer proven durability and reliability, but when an issue occurs, Inovair has industry-leading support. Customer service, engineering, and manufacturing are located at our Inovair headquarters in Kansas City. Thanks to our vertical integration and team collaboration, should an issue arise, Inovair is fast to respond and deliver solutions.

INTEGRATED CONTROL SYSTEMS

Inovair control systems are becoming a revered product in its own right. Simplifying the control systems has meant less downtime and higher reliability for our customers. Using industry-standard components, like Allen-Bradley PLCs, Inovair control systems include several advantageous features:

- - MASS AIRFLOW (SCFM) BASED CONTROL SYSTEM

- - AUTOMATIC TEMPERATURE COMPENSATION

- - AUTOMATIC PRESSURE COMPENSATION FOR VARYING LIQUID LEVELS

- - DO FEEDBACK BASED FLOW CONTROL CAPABLE

- - IN-HOUSE UL CERTIFIED 508A PANEL SHOP

- - ETHERNET (TCP/IP MODBUS) OR HARD WIRE CAPABLE

- - EASY SYSTEMS INTEGRATION

COMPACT, FLEXIBLE FOOTPRINT

Inovair industrial blowers are designed with a robust, proven design utilizing non-contact oil film bearings and an integrated gear case. This allows the use of standard electric motors and Variable Frequency Drives. Inovair's use of industry standard components provides for ease of service, re-use of existing components, and local availability of parts. Most products fit through a standard 36" doorway and in many cases the controls can be mounted in a separate location. Our IM-30 and IM-40 can be stacked for more power and flow per linear square foot.

MADE IN THE USA

Inovair is the only manufacturer of single stage centrifugal industrial blowers and compressors which performs all of its manufacturing activities in the USA. All Inovair products are invented, engineered, machined, assembled and tested in the heartland of the USA at Inovair’s facilities in Kansas City. The design, build quality, performance and durability of Inovair’s geared centrifugal blowers are second to none.

Advantages of "Made in the USA"

- Incentives/Funding

- Industry-Leading Availability

- US-Based Support

- Best-in-class Parts & Service Turnaround

- Highest Quality

Advantages of "Made in the USA"

- Incentives/Funding

- Industry-Leading Availability

- US-Based Support

- Best-in-class Parts & Service Turnaround

- Highest Quality

Inovair Industrial Case Studies

Read specific examples where Invoair has been the most cost effective, reliable solution.

Industrial Case Studies