IM-30 40-250 HP

Industry-Exclusive Design

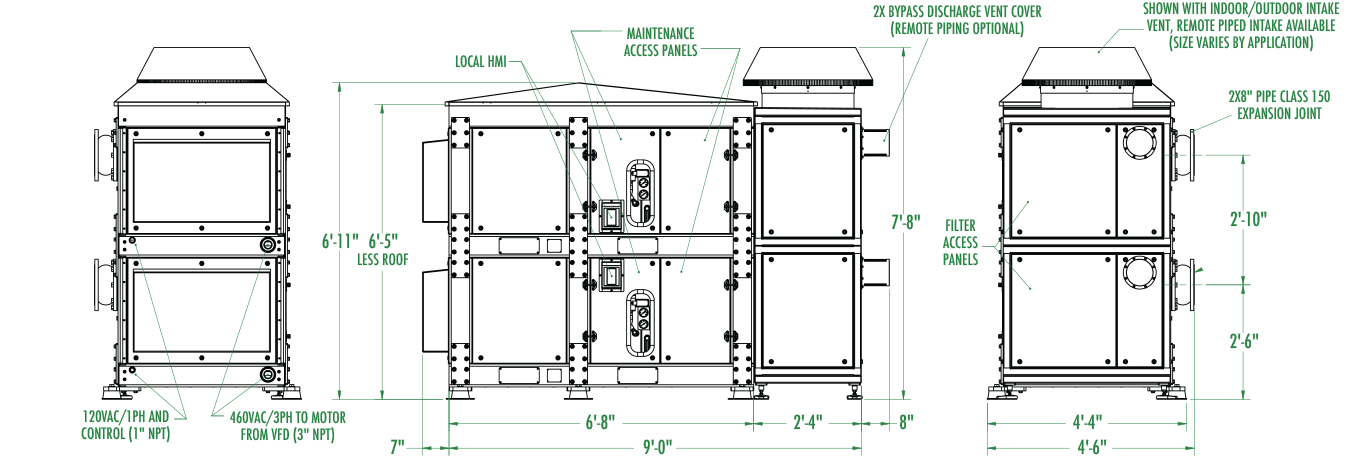

The Inovair IM-30 is the industry’s most flexible high efficiency blower. Designed to be highly reliable and efficient, with the lowest total ownership cost, the IM-30 is the first truly modular blower design. Each module operates independently from any other module. Modules can be deployed as single units or in a stacked configuration.

This innovative blower package also features low noise, minimal maintenance, and the ability to withstand harsh external environments. Thanks to the use of industry standard components, without the electrical complexity seen in high speed turbo blowers, maintenance can be performed at the plant level.

All Inovair blower packages are engineered and manufactured in the USA, with outstanding sales and service support. Inovair is the only manufacturer which offers a single stage high efficiency blower with the advantages of vertical design and manufacturing integration, and US-based production and support.

Many industrial plants suffer from an inability to optimally regulate flow, or expand the blower's capabilities with plant growth. Both of these negatively impact attempts to save energy. The IM-30 solves this problem through modularity without burdening the overall blower footprint.

This innovative blower package also features low noise, minimal maintenance, and the ability to withstand harsh external environments. Thanks to the use of industry standard components, without the electrical complexity seen in high speed turbo blowers, maintenance can be performed at the plant level.

All Inovair blower packages are engineered and manufactured in the USA, with outstanding sales and service support. Inovair is the only manufacturer which offers a single stage high efficiency blower with the advantages of vertical design and manufacturing integration, and US-based production and support.

Many industrial plants suffer from an inability to optimally regulate flow, or expand the blower's capabilities with plant growth. Both of these negatively impact attempts to save energy. The IM-30 solves this problem through modularity without burdening the overall blower footprint.

Standard Specifications

| • Energy Efficient (~80% isentropic) |

| • Proven Integrally-geared Design |

| • Industry Standard Components |

| • Compact Design |

| • Maintenance-friendly |

| • Engineered and Built in the USA |

| • Handles fluctuating pressures |

| • Capable of multiple start/stop cycles every hour |

| • Reduction in capital costs for stand-by units |

IM-30 Features

| • Direct couple drive system |

| • Indoor or outdoor intake vents |

| • Touchscreen interface |

| • Detachable airbox frame |

| • Hinged doors for blower access |

| • Removable access panels |

| • Customizable configuration |

| • Annual maintenance |

IM-30 Benefits

| • Industry-first modular blower design |

| • Up to 4:1 capacity turndown |

| • Greater process flexibility |

| • Up to 50% space savings |

| • Industry-standard components |

| • Low Noise (75-85 dBA) |

| • Available as stacked units, a single unit and/or without frame and enclosure |

Technical Information

| Flow Capacity | 300-4000 scfm |

| Design Pressure | 4-22 psig |

| Turndown Ratio | Up to 4:1 (2:1 per module) |

| Motor Power | 40-250 HP |

| Drive | Standard VFD |

| Input Power | 230V-575V, 60 Hz |

| Impeller | 5-axis machined 7075-T6 Aluminum |

| Control System | Integrated Touchscreen PLC |

Annual maintenance intervals | Up to 2:1 capacity turndown |

Only 2-5 year payback | Up to 50% Space Savings |

Uses Industry-standard VFDs and TEFC motors | Low Noise (80-90 dBA) |