Lowest Cost of Ownership

Inovair Delivers Lowest Total Cost of Ownership

The expense of blower ownership is comprised of equipment, installation, energy, and maintenance costs. Equipment and installation are a one-time expense, while energy and maintenance are continuous costs of ownership, with energy reaching up to 80% of total ownership cost. 1, 2

1 EPA, Report 832-R-10-05, “Evaluation of Energy Conservation Measures”, (September 2010)

2 Gass, J. 2009. Scoping the Energy Savings Opportunities in Municipal Wastewater Aeration. BC Hydro/BCWWA Conference. May 5, 2010

2 Gass, J. 2009. Scoping the Energy Savings Opportunities in Municipal Wastewater Aeration. BC Hydro/BCWWA Conference. May 5, 2010

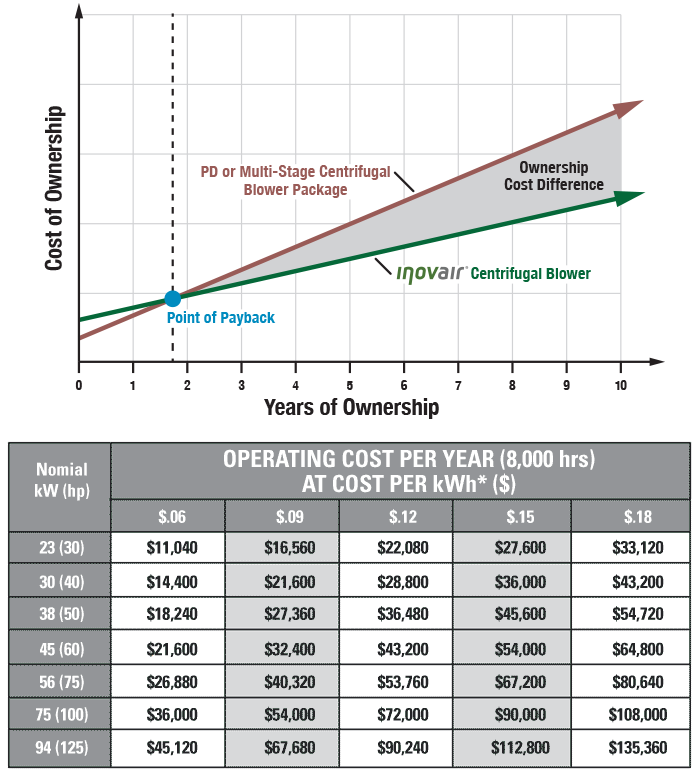

Energy Expense

Best-in-class efficiency produces substantial energy savings (10-40%) relative to positive displacement and multi-stage centrifugal blowers.

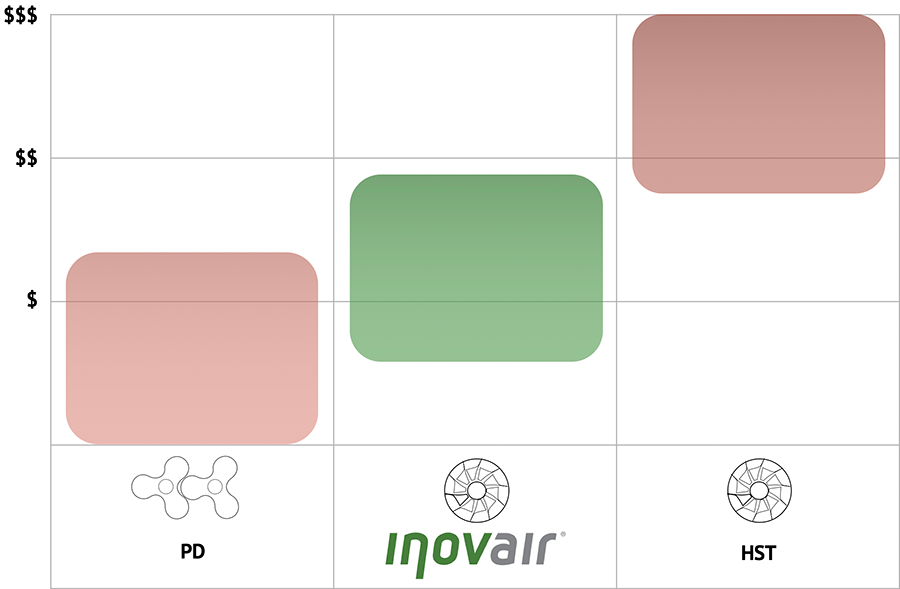

Equipment/Capital Cost

Inovair uses a proven design without exotic electronic components, for improved durability and lower equipment cost. This includes industry standard VFD’s, electric motors and PLC’s in the blower cabinet, and non-contact oil-film bearings and a robust integrally geared design for Inovair head units.

With this approach, Inovair makes high efficiency not only affordable, but also more reliable. Inovair’s flexible design also frequently allows for re-use of existing electric motors and VFD’s if desired.

With this approach, Inovair makes high efficiency not only affordable, but also more reliable. Inovair’s flexible design also frequently allows for re-use of existing electric motors and VFD’s if desired.

Maintenance

Inovair geared centrifugal blowers are built without the electrical component complexity seen in air bearing and magnetic bearing high-speed turbo blowers. Instead, a simpler design using industry standard components allows for easy maintenance at the plant level, as well as greater reliability. Owners of air bearing turbos are finding out that annual maintenance and/or warranty costs can reduce or exceed their annual energy savings. Inovair’s proven design allows for high efficiency, reliability and ease of maintenance.

Inovair blowers are also more reliable than PD blowers and only have an annual maintenance interval.

Inovair blowers are also more reliable than PD blowers and only have an annual maintenance interval.

Installation Flexibility and Cost

Inovair blower packages operate with a much lower dBa level than traditional PD blowers, allowing placement outside of blower rooms. This noise profile, together with novair’s highly durable design, also allows for outdoor placement even when located near residential areas. This can blower installation cost. Inovair’s flexible design also allows for re-use of existing components and infrastructure in many instances, which can also lower installation cost.

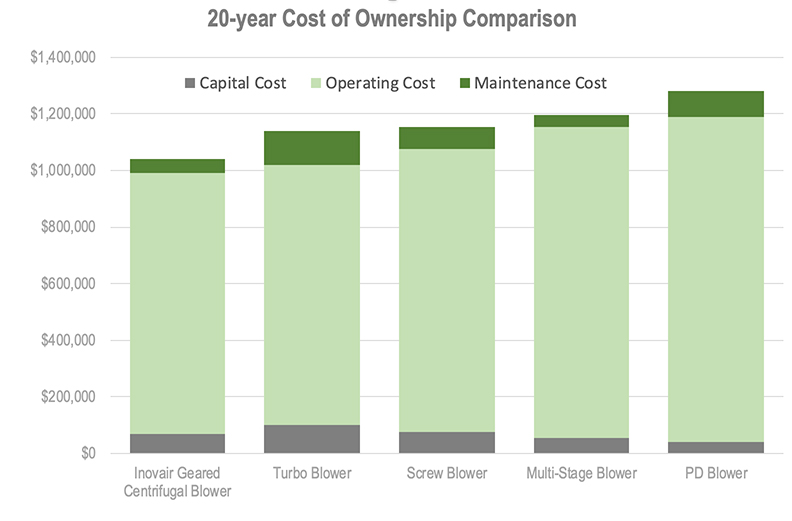

Substantial Savings–A Clear Choice

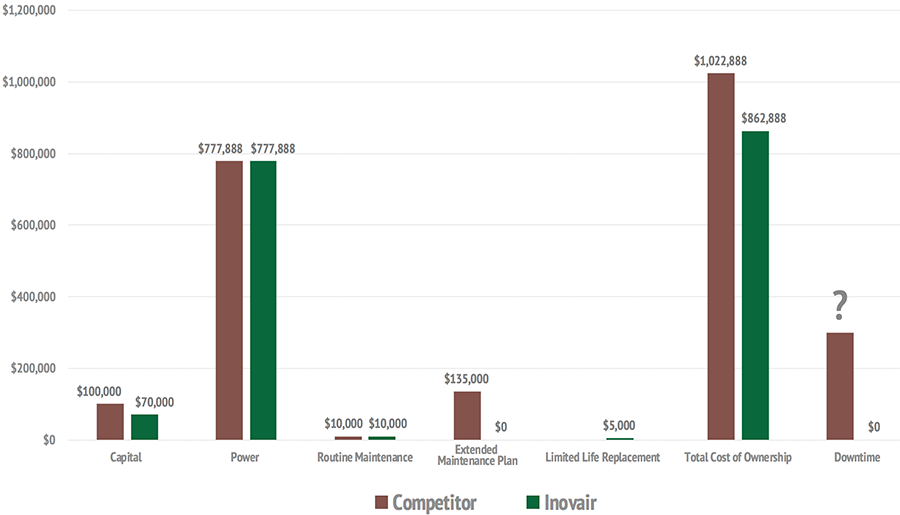

Capital Cost Comparison

Lowest Cost of Ownership

Total Cost of Ownership

Relative to Air-Bearing Turbo