Case Study: New Madrid, MO

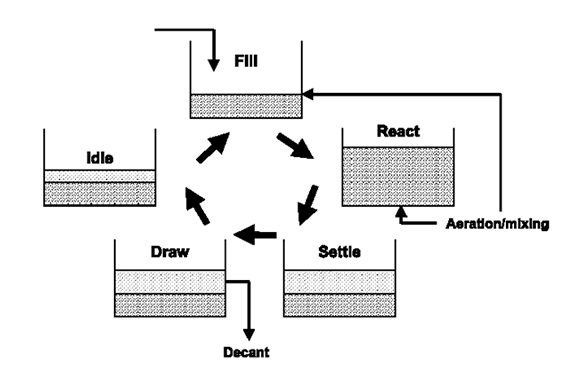

In New Madrid, Missouri, the local wastewater treatment facility implemented SBRs using Inovair blowers. The high-speed blowers demonstrated exceptional reliability and efficiency, handling the frequent start/stop demands without issue. This case study highlights the robustness and suitability of Inovair blowers for SBR processes, leading to significant energy savings and operational stability.