CUSTOMIZABLE CONTROLS

Adaptable & Versatile Control Systems For Wastewater Blower Applications

For many of our applications, controls are essential for providing precise airflow, for both process control and energy savings. Inovair has Master Control Panels (MCP’s) that accomodate the blower function under different conditions and a myriad of different processes. With decades of experience, Inovair has the knowledge and expertise to offer flexible control systems at very cost effective pricing.

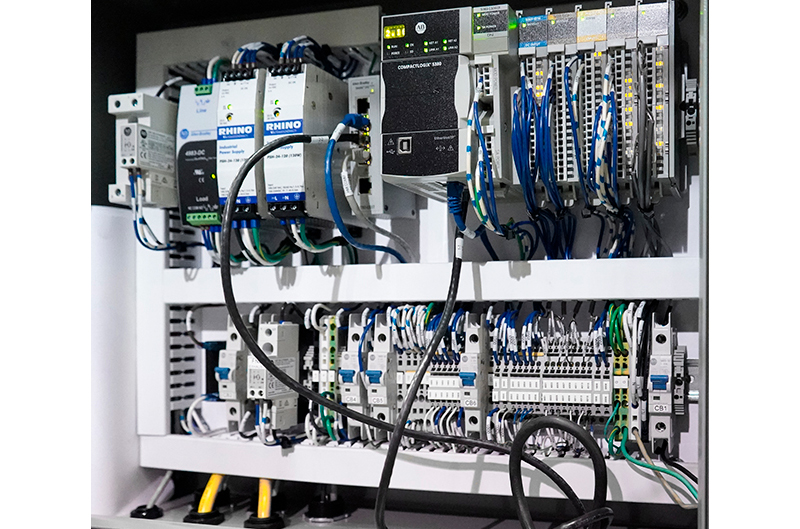

UL 508A-Certified In-House Panel Shop

Inovair can help guide you, whether it is a most-open valve (MOV) scheme or a common-pressure header (CPH) scheme. All of Inovair’s control panels are designed, manufactured and programmed in our Kansas City facility. We have a UL 508A certified panel shop and primarily use industry standard (Allen-Bradley) components.

Optimized Blower Controls For Energy Savings

- Standard and custom master control panels

- Mass airflow (SCFM)-based

- Allen-Bradley PLC’s (CompactLogix, ControlLogix)

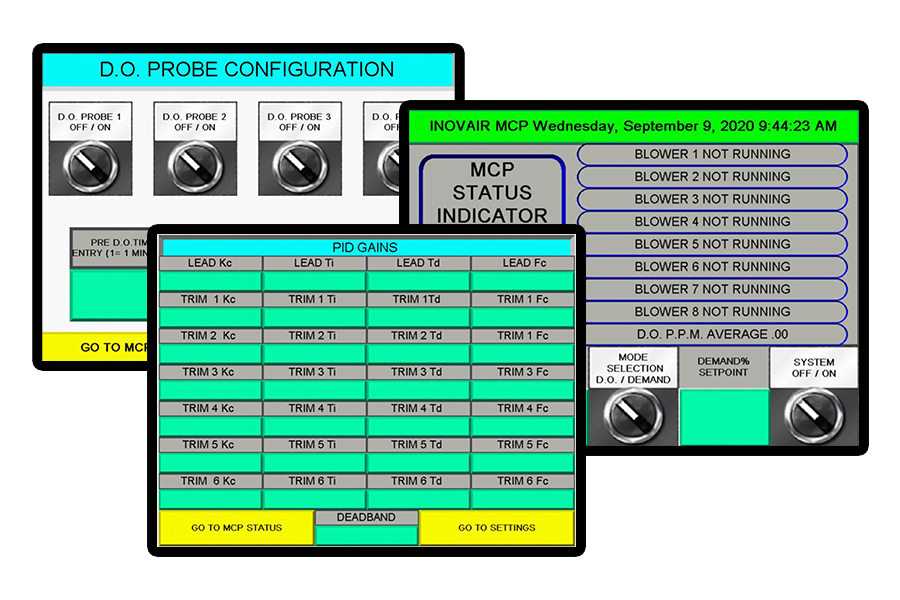

- Multiple sensor inputs (including DO, ORP, PH)

- D.O. feedback based flow control capable

- Standard and custom outputs

- Ethernet (TCP/IP Modbus) or hard wire capable

- Easily integrates into SCADA

Optional Control Functions

Inovair’s control panels offer a variety of standard and optional control functions.

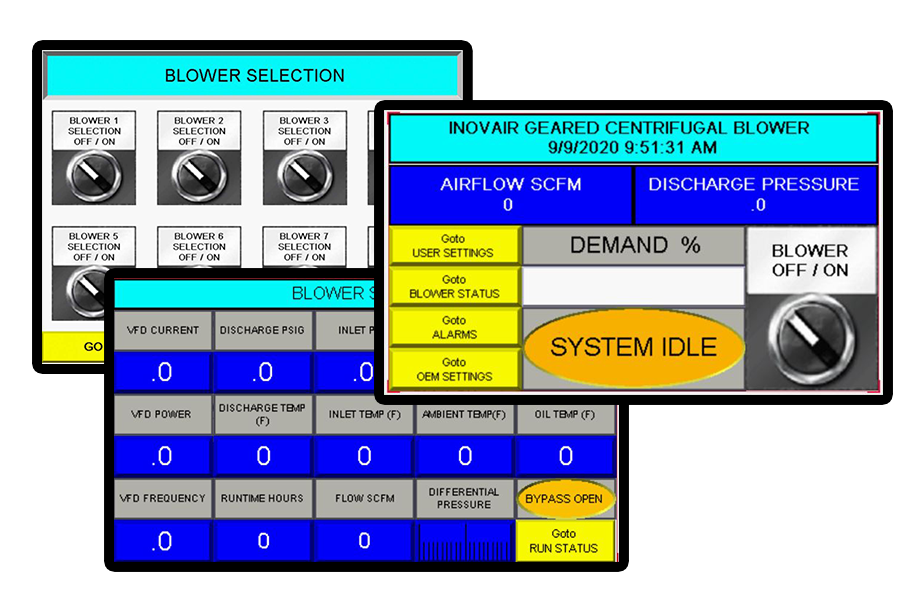

LCP

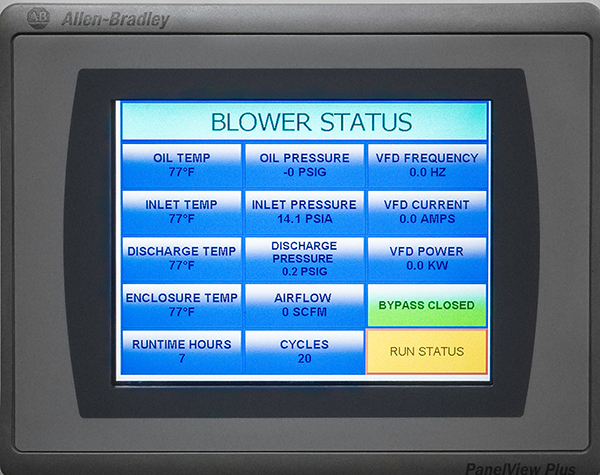

The LCP is capable of manually controlling a single blower and provides energy savings features such as automatic temperature and pressure compensation. This Allen-Bradley CompactLogix-based control system provides excellent process control in single blower applications.

- Mass airflow (SCFM) based control system

- Automatic temperature compensation

- Automatic pressure compensation for varying liquid levels

MCP

The MCP provides single-point of control for multiple blower applications and easily interfaces with SCADA or external sensors (DO, ORP, etc.). It is programmable to operate in either MOV or CPH control schemes and configurable to control other process actuators and relays. Utilizing Allen-Bradley PLC’s (CompactLogix or ControlLogix), the MCP easily integrates into most plants existing control systems or can function as a stand-alone control system.

- D.O. feedback flow control capable

- Balanced run time between multiple blowers

- Lead-lag functionality

- Balancing valve control

- Single point interface

Control Panel Functions

Common Wastewater Applications

- Activated Sludge/Aeration Basins

- Digesters

- Lagoons

- SBRs

- EQ tanks

- MBRs

Let's Talk

Contact our sales team for a quote or more information.