We’ve been designing blowers for nearly 30 years, in some of the most demanding applications. From 4000+ horsepower drag race superchargers to the F-35 fighter jet deicing units, we have the experience and technology to optimize performance and durability. With thousands of Inovair units shipped, we’ve observed energy savings of up to 40%. If you are looking to reduce total cost of ownership, look no further than Inovair.

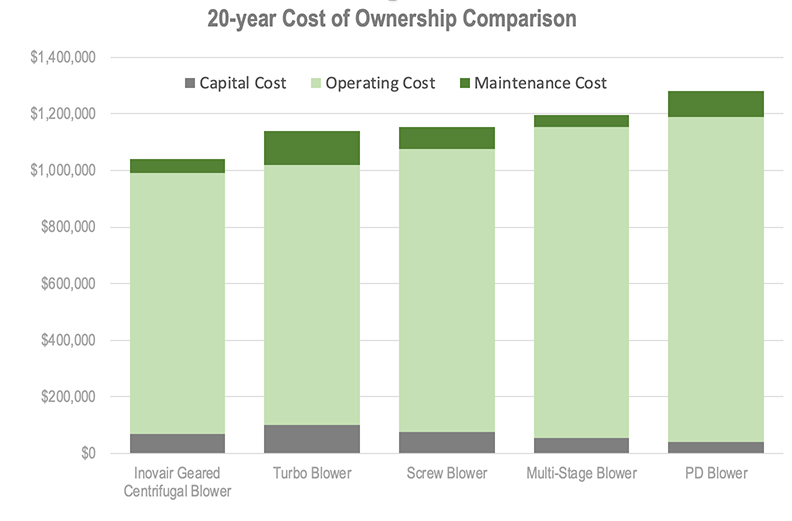

When you consider the cumulative costs of the capital equipment purchase, installation costs, operating costs, maintenance costs, and downtime costs from unplanned equipment issues, Inovair has the best offering on the market. Lowest cost of ownership is our key objective when designing, manufacturing, and supporting our products. Here are some of the key differences that give Inovair an advantage: