Aeration Blowers For Wastewater

The Only High-Efficiency Blowers Made in the USA

The Most Reliable, Cost Effective and

Efficient Blowers

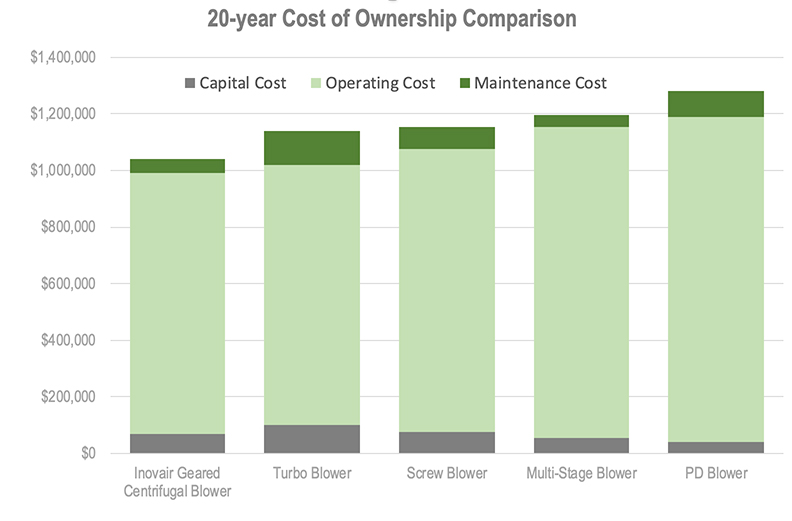

With documented energy savings as high as 45% relative to PD and multistage blowers, and without the electrical complexity and durability issues seen in high speed turbo blowers, Inovair offers a unique combination of high efficiency, reliability, and simplicity. Unlike some others, Inovair blowers and customers are supported by the advantages of a vertically integrated manufacturer, with Inovair controlling all elements of design, production, and service. All of these activities are performed 100% in the USA, at the company’s headquarters in Kansas City.

Proven Performance

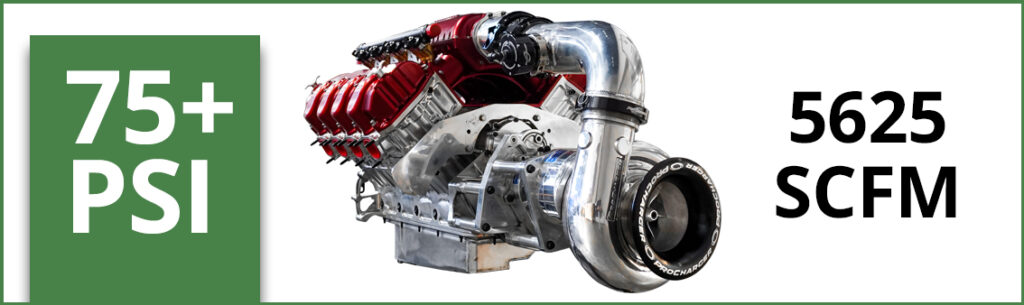

Wastewater Aeration Blower Product Line

LOWEST COST OF OWNERSHIP

HIGHEST EFFICIENCIES

LOW MAINTENANCE COSTS

MINIMAL DOWNTIME

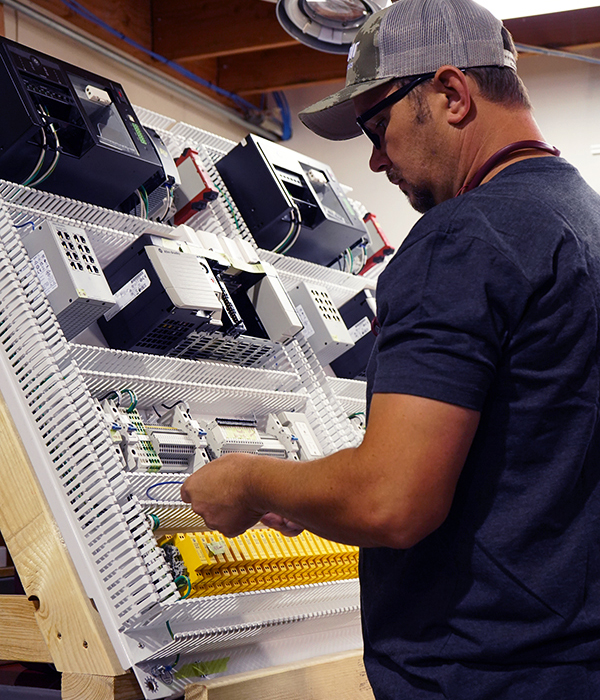

CUSTOMIZABLE CONTROL SYSTEMS

- - MASS AIRFLOW (SCFM) BASED CONTROL SYSTEM

- - AUTOMATIC TEMPERATURE COMPENSATION

- - AUTOMATIC PRESSURE COMPENSATION FOR VARYING LIQUID LEVELS

- - DO FEEDBACK BASED FLOW CONTROL CAPABLE

- - IN-HOUSE UL 508A-CERTIFIED PANEL SHOP

- - ETHERNET (TCP/IP MODBUS) OR HARD WIRE CAPABLE

- - EASY SYSTEMS INTEGRATION

COMPACT, FLEXIBLE FOOTPRINT

MADE IN THE USA

Advantages of "Made in the USA"

- Incentives/Funding

- Industry-Leading Availability

- US-Based Support

- Best-in-class Parts & Service Turnaround

- Highest Quality

Inovair Wastewater Aeration Blower Case Studies

Read specific examples where Invoair has been the most cost effective, reliable solution.

Wastewater Case Studies“The Inovair blowers required half the horsepower of our old blowers. They are a quiet, cost effective and compact package which has all around exceeded our expectations. If another plant manager asked my advice, I’d tell them to definitely go with Inovair”

Josh YoungbloodAssistant Water Quality Superintendent, Nixa Wastewater Treatment Plant

“I was very impressed with the efficiency of these units. The Inovair blowers provided more airflow with reduced kW consumption and maintained a more consistent DO level”

Jesse CoxSuperior Electrical Contractors

“Following a side by side evaluation comparing the energy consumption between the IM blowers and the positive displacement blowers, the Inovair blowers exceeded the anticipated energy savings. Along with the energy efficiency [37% reduction in energy consumption] we believe the operation and maintenance costs of the equipment will also result in additional savings. The entire Inovair team was extremely informative and helpful”

Jeff MockPublic Works Operations Manager, Blue Springs, Missouri

“With 45% energy savings over our previous multi-stage blowers, this project pays for itself very quickly”